Glass printing and processing

With full-cover color application, individual printing or precise laser processing, our glass can be permanently refined in a wide variety of ways.

Printing on glass with intense organic colors

Spraying on glass with organic colors (two-component colors) enables a high-coverage application of color. After several days’ drying time, the paint is finally hard and should be protected from scratches and moisture. Only single-color full- or partial-cover prints are possible. Sprayed glass is often used in interior design when bonding or installations behind the glass need to be covered.

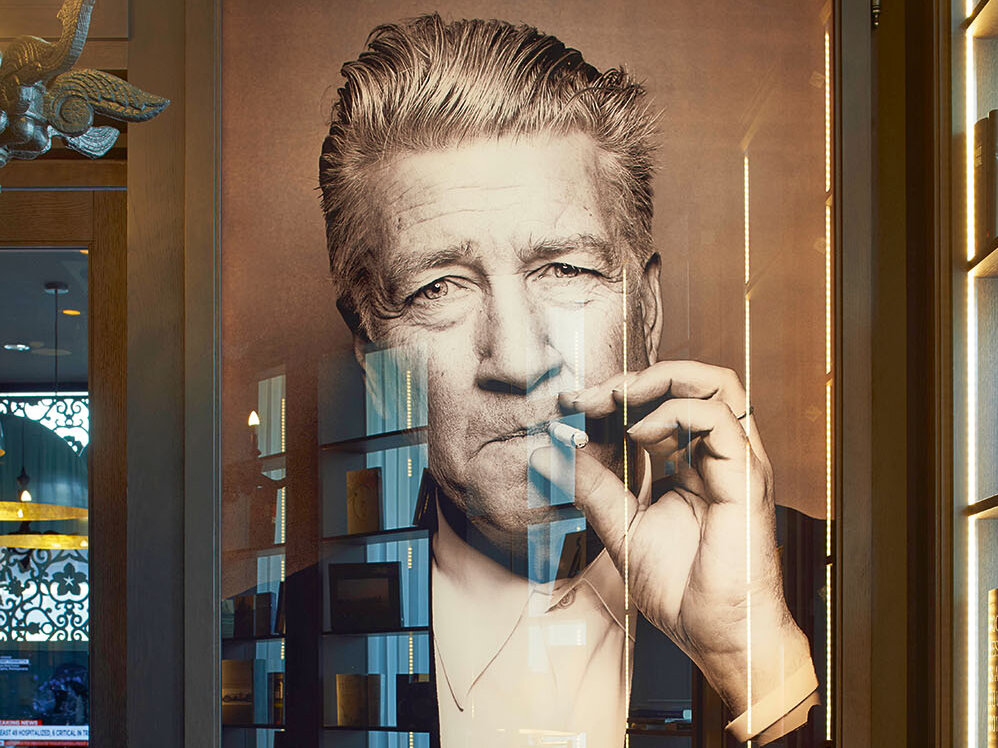

Printing on glass with high-resolution digital technology

With the digital printing process, all glass sizes as well as films can be printed in high resolution. All conceivable multicolored motifs, photos, images or even patterns can be applied very realistically. Digital printing techniques are also used for very small print runs from just one piece. However, this method is not suitable for full-surface single-color prints.

Different procedures are available, depending on the specific requirements:

COLORPRINT FP

When printed in combination with laminated safety glass (LSG), the motifs can be applied to a PVB film. In the lamination process, the printed film is bonded between two panes of glass. This protects the colours almost completely from UV radiation, so that the print does not show any yellowing even after several years. The printed colours are translucent. In combination with different base films, very special effects can be achieved. For example, images can also be displayed opaquely.

COLORPRINT CP

The digital data processing also allows colours to be reproduced from different ceramic colour systems. As with screen printing (DECO SC), the application of ceramic paints on glass is carried out using a thermal tempering process which burns the colour permanently into the glass. The end product is a single-pane safety glass or heat-strengthened glass (HS) with the respective physical and mechanical properties. The applied colour is scratch- and abrasion-resistant, weather-resistant, lightfast and largely solvent-resistant. The printed motif is visible from both sides.

COLORPRINT HD

For printing motifs of any kind indoors, in particular, the glass – float, ESG or LSG – is printed with organic UV-curable colours. The hardening is completed at the same time as printing and is complemented by a protective coating.

Glass refinement by precise laser engraving

LASER DESIGN is synonymous with crisp images on glass in which even the tiniest details and finest lines become visible. Almost any graphic, motif, image or photo can thus be shown accurately to best advantage.

The engravings can be made either on the glass surface or inside the glass (VSG). The laser processing of glass is also best suited for light extraction with LED. The translucent and refractive images lend a special impression of depth. Laser engravings are resistant to abrasion and impact, are durable, insensitive to heat influences and liquids, and easy to clean. The enhanced slip resistance is certified in accordance with R9 and R10.

Processing of glass for non-slip surfaces

ANTIGLISS is synonymous with non-slip surface finishes such as those required for walk-in glass, for example. The non-slip effect can be achieved either by etching, screen printing, sandblasting or laser engraving. No matter which method is used, ANTIGLISS always offers maximum safety and a wide range of design options.

Printing on glass with permanent ceramic colors

When printing with ceramic colors, the colors are applied to the glass with a sieve or roller and pre-dried. In the second step, the applied colors are permanently fired into the glass by the thermal tempering process.

The end product is a single-pane safety glass or heat-strenghtened glass (HS) with the respective physical and mechanical properties. The applied colour is scratch- and abrasion-resistant, weather-resistant, lightfast and largely solvent-resistant.

Depending on the specific requirements, the ceramic colours are applied using screen printing (SC) or rolling (RC).